Some Ideas on Premier Aluminum Llc You Need To Know

Table of ContentsA Biased View of Premier Aluminum LlcThe 9-Second Trick For Premier Aluminum LlcHow Premier Aluminum Llc can Save You Time, Stress, and Money.The Best Strategy To Use For Premier Aluminum LlcAbout Premier Aluminum Llc

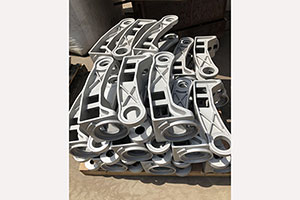

When selecting a light weight aluminum shop for your manufacturing requirements, it's important to study a number of variables. One of one of the most important elements to think about is the experience and skills of the foundry. Selecting a factory who has the appropriate knowledge of the light weight aluminum casting process, and the profile to reveal for it, aids to have a successful end result for your project.Having the experience and sector expertise to engineer your castings for ideal production and top quality outcomes will improve the job. Making aluminum castings needs a complicated collection of processes to attain the best outcomes. When picking a new light weight aluminum foundry to partner with, guarantee they have comprehensive sector experience and are well-informed regarding all elements of the light weight aluminum casting process: style, manufacturing, product analysis, and product testing.

The foundry ought to also have a proven performance history of providing remarkable items that satisfy or exceed client expectations. Quality assurance needs to also go to the top of your list when choosing a light weight aluminum factory. By working with a certified shop who adheres to the requirements for quality assurance, you can secure the integrity of your product and ensure it fulfills your requirements.

The Best Strategy To Use For Premier Aluminum Llc

Numerous parts that really complicated shapes can be made using this process. Prior to you begin looking for a trustworthy light weight aluminum pass away caster, there are some crucial points that you require to do.

You have to ask on your own what type of light weight aluminum pass away castings you require. After establishing what you call for, you have to mention the requirements of the light weight aluminum pass away castings you require.

Do you know just how much money you need to spend on the products? In order to do this, the most effective thing to do is to establish the number of light weight aluminum diecasts you call for. After having this info, you can start researching aluminum die-casting manufacturers. You can do this by simply typing the key phrase" Aluminum die casting producers" on the Google internet search engine.

Some of the inquiries you require to ask yourself are whether they have experienced and trained operators, the length of time their service has functioned, or if they have some accomplishments. You can frequently get the response to these concerns from the manufacturer's website. You can look into other internet sites or outside sources to verify if the info provided on the producer's website is genuine.

The 25-Second Trick For Premier Aluminum Llc

One more point you need to take into consideration is the maker's capability to produce light weight aluminum die-casting items. To put it simply, the quantity of items the manufacturer can generate at a given time. Some of the essential questions you require to ask yourself are whether the manufacturer can generate a greater volume or can the manufacturer fulfill your needs.

(https://canvas.instructure.com/eportfolios/3385397/home/premier-aluminum-llc-your-trusted-aluminum-casting-company)What happens if your firm needs 10,000 items of particular maker components from the supplier within one month? You bought this amount; however, the manufacturer can just produce 5000 items of these machine components within one month (Casting Foundry). Because of this, you will not have the ability to get the quantity that you purchase in a timely manner

4 Simple Techniques For Premier Aluminum Llc

It is important that you should make inquiries if the producer is applying an in-house tooling procedure. In addition, you have to ask the supplier just how a lot the cost of internal tooling is. Bear in mind that the in-house tooling process, which permits you to create unique styles and forms can be an added expense.

This facet directly correlates with the maker's production capacity. Aluminum Casting. You have to look for a supplier that can make certain quicker delivery of products.

This suggests that there are discover here several alternatives that you can pick from. Today, customer needs continue changing. It appears that clients are looking for a superb combination of high quality, cost-effectiveness, and longevity. That is why it is greatly recommended that you must choose a producer that can produce various sorts of light weight aluminum die-cast products.

Premier Aluminum Llc Fundamentals Explained

Many frequently, these light weight aluminum die-casting items will call for some decors, machining, or finishing touches. Having this in mind, you ought to look for a supplier that can execute a range of secondary completing jobs once pass away casting is done. Some examples of completing operations include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Damp paint, Plating, and many even more.

Die spreading is one of the most cost-effective, precise, and protean production processes in the world moment. The process involves fitting molten significance, under stress, into an applicable die (planet), and formerly solidified it can be expelled and completed (if required) in a selection of methods. The dies are [...].